A coordinate measuring machine, also known as a CMM, is a piece of equipment that utilizes a precise electronic probe to take measurements of discrete points on an object.

Applications for Coordinate Measuring Machines, also known as CMMs, can be found in a wide variety of business sectors. They are typically applied in this context for quality control purposes. CMMs are also put to use in the automotive industry for the purpose of measuring suspension hardpoints for the purpose of using those measurements in vehicle dynamics simulations.

In spite of the fact that many businesses provide measurement services using a FARO arm or a Hexagon/Romer arm, the fact that we have extensive experience in the automotive industry makes us the most qualified option for coordinate measuring machine (CMM) inspection of suspension hardpoints.

We are able to measure the XYZ coordinates of suspension pick-up points, chassis reference locations, drive-train reference locations, cmm inspection services and body reference locations for whole vehicles and/or sub-assemblies of whole vehicles. Work involving computer modeling and vehicle simulation, as well as evaluating the build quality of vehicles, will benefit tremendously from having this information. The in-house Hexagon Absolute Arm that we have is readily available for use as an add-on to a K&C test. In this capacity, it is able to quickly and easily measure the deflection of components while they are subjected to realistic loading conditions.

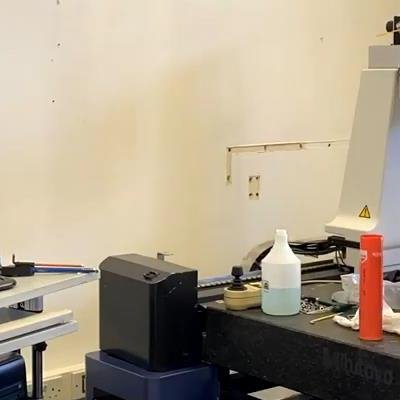

The method cmm services (please click here to buy it) we use with our Coordinate Measuring MachineThe K&C rig that we have offered a one-of-a-kind reference that is ideal for vehicle CMM work. A plate with a plane surface that has been precisely ground and is conveniently located five feet off the ground makes up the middle section of the rig.

The rig allows for excellent accessibility to key measurement locations (such as the geometry of the suspension pick-up point), and the staff at Morse Measurements is focused on vehicles. Complex CMM measurements can be simplified into actionable results that can be used for vehicle design validation as well as computer modeling.

The coordinate measurements are taken with a Hexagon Absolute arm that is located in-house. In most cases, CMM Inspection Companies the complete geometry of the vehicle suspension pick-up point can be measured in just one day. You are given an easy-to-read and comprehended spreadsheet that contains the XYZ coordinates in the reference frame of your choosing. In the event that you require additional information or constructions, these are made available to you as well as the raw data files. IGS files can also be delivered if that is something that is requested.

The Benefits of Using a CMM at Morse MeasurementsIn order to guarantee accurate geometry measurements, our K&C rig provides precise vehicle alignment in relation to a ground plane reference that is already known. In addition, the vehicle is very easy to access, so it is not necessary to remove any bodywork or other components in order to get to the important measurement locations. The K&C rig that we use for performing CMM measurements is conceptualized by our team as a surface plate that is handily positioned five feet in the air.

Quality: Because we have previous experience with vehicle modeling, we are aware of what it is that we are attempting to quantify. We take the time to condense all of the CMM information into its most essential components in order to provide you with the data you require with as little hassle as possible. For instance, we locate accurate ball joint centres and reference axes that are comprehensible to engineers working on vehicles. The measurements provided by a CMM are an excellent supplement to K&C testing.